Brief Introduction of Polycarbonate Materials

Information of Polycarbonate

| Features | Info |

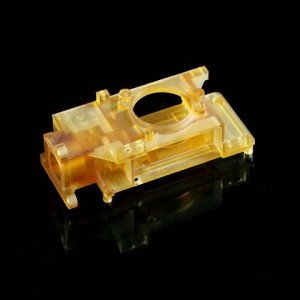

| Color | Clear, black |

| Process | CNC machining, injection molding |

| Tolerance | With drawing: as low as +/- 0.005 mm No drawing: ISO 2768 medium |

| Applications | Light pipes, transparent parts, heat-resistant applications |

Material Properties

| Tensile Strength | Elongation at Break | Hardness | Density | Maximum Temp |

| 8,000 PSI | 110% | Rockwell R120 | 1.246 g/㎤ 0.045 lbs / cu. in. | 180° F |

General Information for Polycarbonate

Polycarbonate is a durable material. Although it has high impact-resistance, it has low scratch-resistance.

Therefore, a hard coating is applied to polycarbonate eyewear lenses and polycarbonate exterior automotive components. The characteristics of polycarbonate compare to those of polymethyl methacrylate (PMMA, acrylic), but polycarbonate is stronger and will hold up longer to extreme temperature. Thermally processed material is usually totally amorphous, and as a result is highly transparent to visible light, with better light transmission than many kinds of glass.

Polycarbonate has a glass transition temperature of about 147 °C (297 °F),so it softens gradually above this point and flows above about 155 °C (311 °F).Tools must be held at high temperatures, generally above 80 °C (176 °F) to make strain-free and stress-free products. Low molecular mass grades are easier to mold than higher grades, but their strength is lower as a result. The toughest grades have the highest molecular mass, but are more difficult to process.