The manufacturing sector is among the most dynamic industries. Today, there is a relentless push to enhance the overall precision and accuracy and processes like wire EDM that deliver precisely that are nothing short of transformative for the industry.

So, what’s Wire EDM exactly, and why is it considered a game-changer for the manufacturing sector? The following text will take a look at the basics of this sophisticated manufacturing technique with applications across different industries.

A Brief Introduction to Wire EDM

Wire Electrical Discharge Machining (EDM) was pioneered in the 1940s by two Soviet scientists who first eroded metal with electrical discharge. The technology saw significant advancements in the 60s and 80s, becoming more commercially prevalent in manufacturing. By the late 90s, with IT and CNC enhancements, wire EDM machines became more computerized, boosting their efficiency and precision.

Today, Wire EDM is essential in industries like Aerospace, Automotive, and Medical, known for delivering intricate designs and complex forms unmatched by traditional machining methods.

The Wire EDM Process

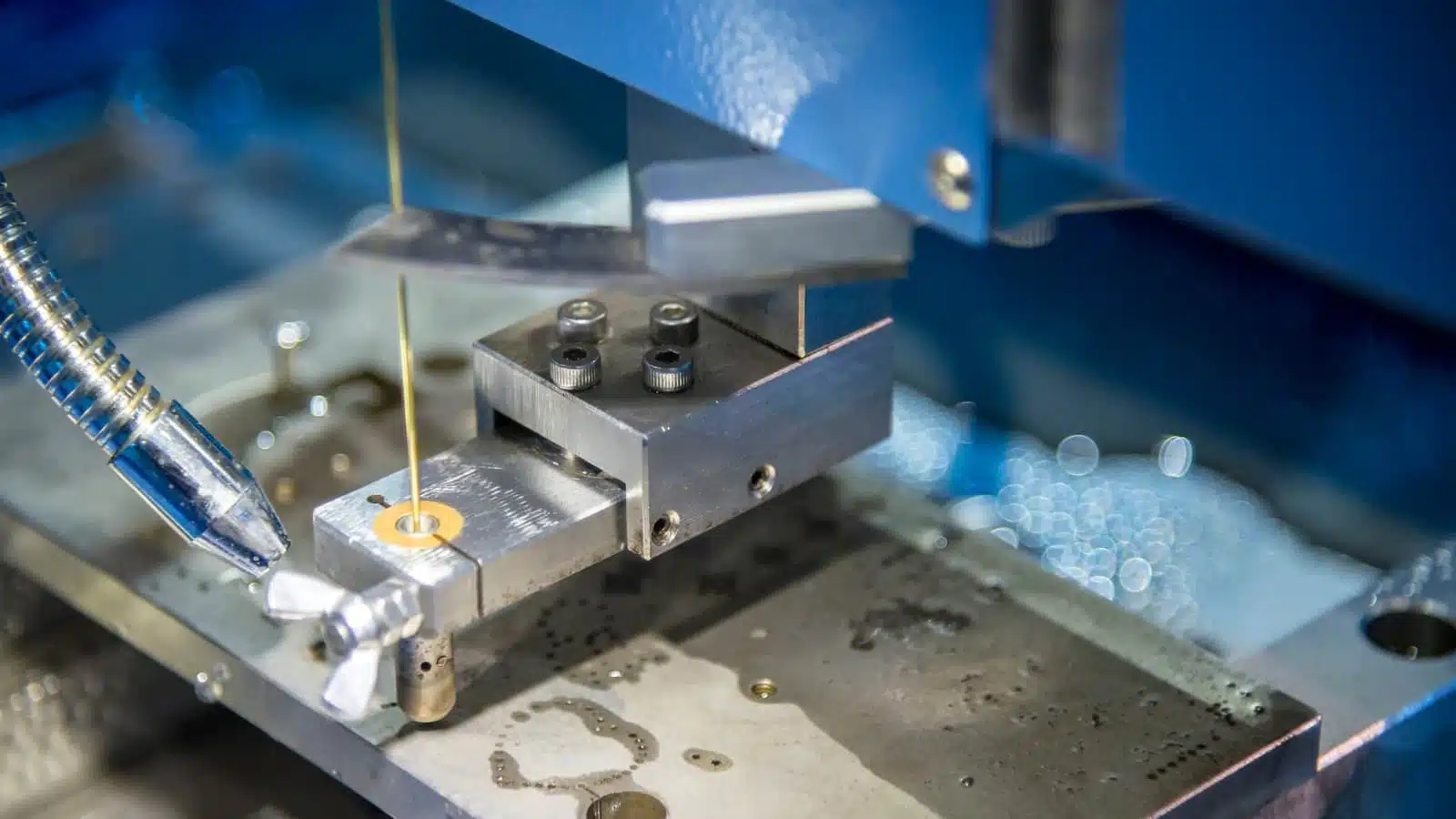

Wire Electrical Discharge Machining (EDM) is a precise method that uses controlled electrical sparks to melt tiny parts of a workpiece. The wire electrode, typically made of brass or zinc-coated materials, creates this spark and moves in a pre-set path. Its advantage? It works without physical contact, preventing any damage or marks on both the workpiece and the tool.

How EDM Works

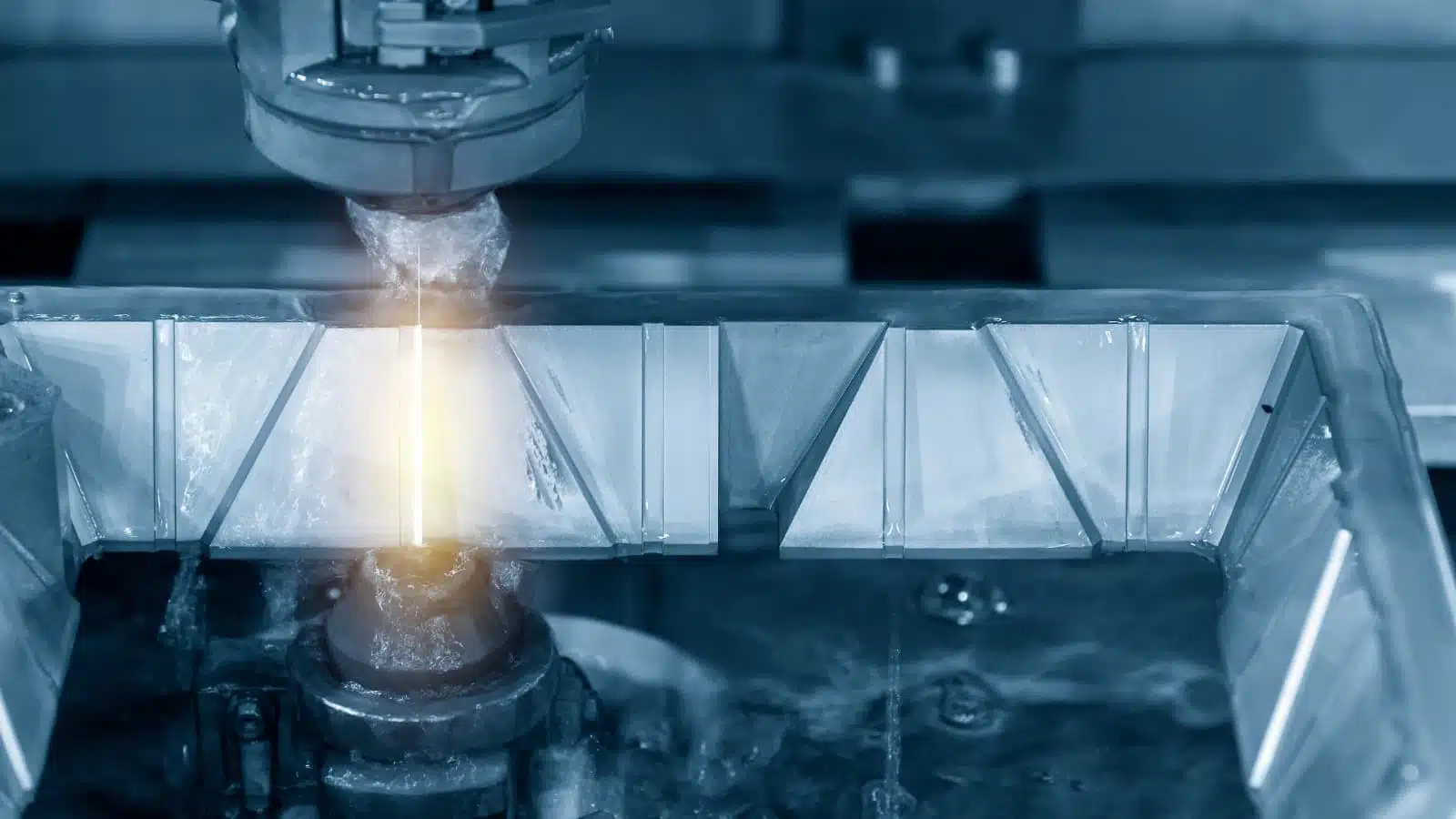

EDM hinges on thermal energy from electrical discharge. This discharge heats the workpiece to its melting point, forming tiny plasma channels. These channels, often micrometer-sized, can disappear quickly.

The EDM process occurs in a dielectric medium, usually deionized water. This fluid cools the workpiece and removes vaporized material, aiding in continuous machining.

Significance of the Wire Electrode

Acting as both a cutter and conductor, the wire electrode is vital. Coated with materials like brass or zinc, it resists reactions at high temperatures. Controlled by a computer, it ensures accurate cuts with minimal distortion and high precision.

Tolerances for Wire EDM

Wire cutting is among the most precise manufacturing processes there are. So, tight tolerances are not out of the ordinary for it. The actual tolerance depends on several factors including the project’s intricacies, machining capabilities, and the operator’s skills.

However, the standard and acceptable tolerances are an industry benchmark that a lot of manufacturers follow.

Standard Tolerance and Fine Tolerance

Standard Tolerance

Linear Tolerances: Typically range from ±0.005 to ±0.001 inches (0.127 to 0.0254 mm), indicating the permissible deviation for features like holes, slots, or profiles.

Hole Diameter Tolerances: Usually between ±0.0005 to ±0.001 inches (0.0127 to 0.0254 mm), ensuring machined holes stay within the defined diameter.

Fine Tolerance

Linear Tolerances: Achieves precision at the micron level, typically ranging from ±0.0002 to ±0.0001 inches (0.0051 to 0.00254 mm), vital for applications needing utmost accuracy.

Hole Diameter Tolerances: Ranges from ±0.0001 to ±0.00005 inches (0.00254 to 0.00127 mm), highlighting Wire EDM’s exceptional precision.

Factors Affecting Tolerances in Wire EDM

Wire EDM is famous for its micron-level precision, making it ideal for intricate applications. However, its precision isn’t fixed and hinges on several factors:

•Machine Stability: A stable machine ensures better precision in cutting actions.

•Wire Quality and Diameter: Its purity, diameter, and electrical traits influence the machining process. Optimal results require a balance between wire quality and diameter.

•Workpiece Material: While some materials are more accessible to machines, the material choice must align with the application’s needs.

•Flush Conditions: The flow of the dielectric medium, affects the quality of the machining process, aids in material removal, consistent electrical discharges, and effective heat dissipation.

•Machine Calibration and Maintenance: The machine’s capabilities are pivotal. Superior machines with adept operators are essential for achieving the best tolerances.

•Thermal Stability: To maintain the known precision of Wire EDM, controlled electric arcs are crucial. Thermal instabilities can jeopardize accuracy, emphasizing the importance of consistent conditions.

The Most Suitable Materials for Wire Cutting

Ferrous Metals

Stainless Steel

It combines durability with excellent electrical conductivity. Its ability to resist corrosion makes it a sought-after material in various industries. In the context of machining, its compatibility with precise and detailed designs stands out.

Tool Steel

Renowned for its hardened attributes, tool steel is the backbone of many heavy-duty tools and precision parts. Its inherent toughness, when coupled with its electrical properties, makes it a prime candidate for intricate detailing and long-lasting sharpness.

Carbon Steel

A versatile player in the metals domain, carbon steel, though less machinable than its counterparts, can be tailored to perfection with the right electrode choices and operational parameters. Its affordability combined with its performance makes it a staple in many industries.

Alloy Steel

An amalgamation of elements, alloy steel’s performance is a tapestry of its components. Depending on its unique blend, it can offer strength, durability, and machinability, making it a dynamic choice for varied applications.

Non-Ferrous Metals

Titanium

Often termed the ‘space-age metal’, titanium’s robustness and high melting point pose challenges in conventional machining. However, when chiseled with precision tools, it unveils designs that are both intricate and resilient, making it a favorite for aerospace and medical industries.

Aluminum

The darling of lightweight metals, aluminum is celebrated for its splendid electrical conductivity and malleability. It not only offers ease of machining but also promises strength without the burden of weight, making it pivotal in industries from transportation to packaging.

Copper

A conductor par excellence, copper is at the heart of many electrical and electronic marvels. Its natural reddish-orange hue combined with its ability to be shaped into detailed components makes it indispensable in everything from electronics to decorative arts.

Brass and Bronze

These alloys, resplendent in their golden tones, are not just about aesthetics. Their commendable electrical properties make them go-to materials for components where precision meets beauty, such as in ornate jewelry or finely made electronic parts.

Key Applications of Wire EDM in Modern Engineering

Wire EDM machining is gaining traction due to its versatility in handling diverse materials and its ability to achieve precise details and tight tolerances, making it pivotal in modern manufacturing. Here are three primary applications:

Precision Parts Manufacturing

The common choice for manufacturing high-precision parts with tight tolerances. It excels in producing complex shapes, fine details, and small features in various materials.

Industries such as aerospace, medical, automotive, and electronics rely on Wire EDM to create critical components like gears, nozzles, connectors, and intricate molds.

Tool and Die Production

Wire EDM is instrumental in forging molds, dies, and specialized tooling, catering to processes from injection molding to stamping. The method’s prowess in upholding exact dimensions and carving sharp angles ensures premium quality and uniformity in large-scale production.

Prototype Development

For swift and precise prototyping, engineers and innovators gravitate towards Wire EDM. This expedites design validation and rigorous testing phases.

Prototypes chiseled via Wire EDM closely mirror the end product, reinforcing its significance in the product evolution cycle.

Given its strengths in these core areas, Wire EDM’s precise and accurate capabilities are leveraged extensively across numerous industries.

•Medical Device Manufacturing

•Electronics and Micro-components

•Aerospace and Aviation

•Jewelry and Watchmaking

•Automotive Industry

•Energy Sector

•Mold and Die Repair

Post time: Dec-12-2023