Naita and Lijin Technology will jointly develop a 20,000 ton capacity injection molding machine, which is expected to reduce the production time of automobile chassis from 1-2 hours to 1-2 minutes.

The arms race in China’s electric vehicle (EV) industry extends to large injection molded vehicles.

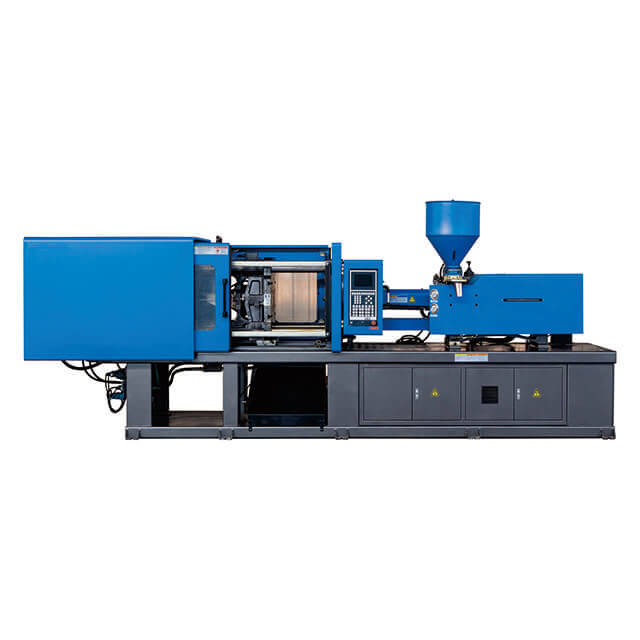

Neita, a brand of Hozon Automobile, announced today that it signed a strategic cooperation agreement with Lijin Technology, a complete injection molding machine manufacturer listed on the Hong Kong Stock Exchange, on December 15 to jointly develop 20,000-ton injection molding equipment.

This equipment will be the most powerful in its field in the world, surpassing the 12,000-ton injection molding machines currently used by Xpeng Motors (NYSE: XPEV), Tesla (NASDAQ: TSLA) and Aito’s 9,000-ton injection molding machine under pressure. Neta said, as well as the 7,200-ton injection molding machine used by Zeekr.

Neta said the equipment will use integrated injection molding technology for larger parts, including the chassis of B-class cars, allowing the production of a skateboard chassis in 1-2 minutes.

Neta will also acquire several large-scale injection molding machines from Lijin Technology and form a joint venture to build an injection molding demonstration production base in Anhui Province in eastern China.

Neta’s press release notes that integrated injection molding equipment can combine individual components, significantly reducing the number of parts in a vehicle and lowering production costs compared to traditional production methods.

Neta said the technology could reduce vehicle chassis manufacturing time from the traditional 1-2 hours to 1-2 minutes, and also help reduce vehicle weight and improve vehicle comfort.

Neta said the establishment of a 20,000 tonne injection molding plant is important to reduce costs and will help the company achieve its goal of selling more than 1 million vehicles worldwide by 2026.

Netta was founded in October 2014 and released its first model in November 2018, becoming one of the first new automakers in China.

Earlier this year, the company said it plans to enter the market in more than 50 countries and regions by 2024 and plans to sell 100,000 units overseas next year.

On October 30, Neta said it aims to become a global high-tech company with global sales of 1 million vehicles by 2026.

According to the company, Lijin Technology is the world’s largest injection molding machine manufacturer, with a market share of more than 50% in mainland China.

At present, many Chinese electric vehicle manufacturers have introduced large-scale injection molding machines. Xpeng Motors uses a 7,000 ton injection molding machine and a 12,000 ton injection molding machine to produce front and rear car bodies in its Guangzhou plant. X9.

CnEVPost visited the factory earlier this month and saw two large injection molding machines, and also learned that Xpeng Motors will begin production of a new 16,000-ton injection molding machine in mid-January.

Post time: Apr-25-2024