Subheadline: Guansheng Precision Machinery Powers Innovation with Multi-Axis Expertise

In the competitive landscape of precision manufacturing, the choice between 3-axis and 5-axis CNC machining fundamentally shapes production capabilities. Traditional 3-axis systems, operating along linear X, Y, and Z paths, remain highly efficient and cost-effective for parts with simpler geometries or planar surfaces. They continue to serve vital roles across automotive, construction, and general industrial sectors.

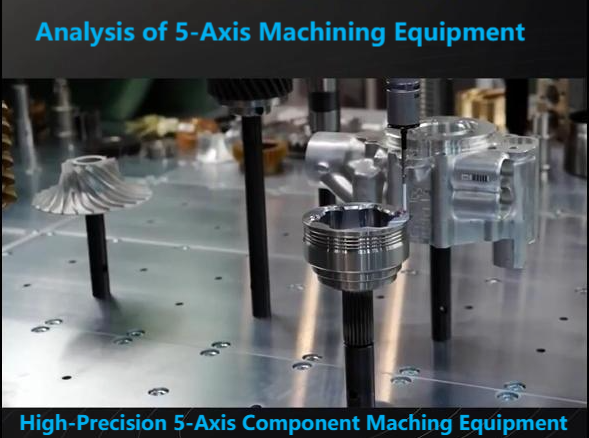

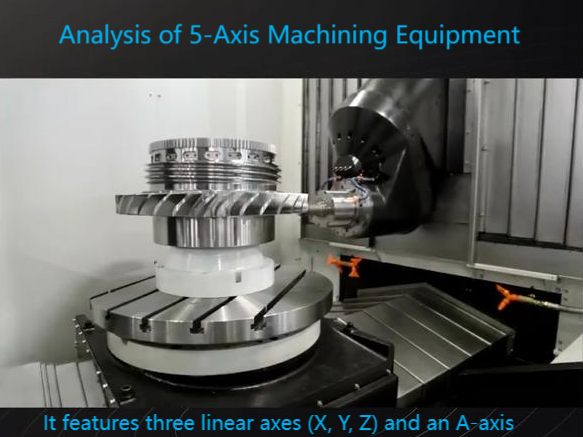

However, the demand for intricate, high-tolerance components is driving a significant shift towards 5-axis CNC machining. By integrating two rotational axes (A and B, or A and C) with the linear axes, 5-axis machines enable simultaneous five-axis movement. This allows cutting tools to access hard-to-reach geometries from virtually any angle in a single setup. The result is unparalleled precision for complex contours, reduced production time by eliminating multiple fixtures, minimized human error, and superior surface finishes. These advantages make 5-axis technology indispensable in aerospace, advanced medical devices, high-performance automotive, and defense applications.

Leading this technological evolution is Xiamen Guansheng Precision Machinery Co., Ltd. Founded in 2009, Guansheng has established itself as a comprehensive manufacturing partner, integrating R&D, production, processing, sales, and service. Catering to mission-critical industries including aerospace, automotive, robotics, medical, and telecommunications, the company understands the nuanced demands of precision engineering.

Guansheng’s strategic investment in over 150 advanced CNC machines – encompassing 3-axis, 4-axis, and 5-axis systems – positions it uniquely. This extensive capacity, combined with expertise in processing 100+ diverse materials and applying specialized surface finishes, enables Guansheng to guarantee both rapid turnaround and exceptional quality. From disposable prototypes to high-volume production runs, the company delivers reliable, turnkey solutions for the most challenging precision parts, leveraging the full spectrum of multi-axis machining capabilities to drive client innovation forward.

Post time: Jul-14-2025