In CNC machining, quality inspection is not a separate step at the end of production, but an integral part of ensuring dimensional accuracy and functional reliability. At GSG-Tech, inspection and measurement are applied throughout the manufacturing process to support stable and repeatable results.

Inspection Focus Based on Functional Requirements

Not all dimensions require the same inspection approach. For most industrial components, only specific features directly affect assembly or performance. Inspection efforts are therefore focused on critical dimensions such as hole positions, mating surfaces, and geometric relationships.

By aligning inspection scope with functional requirements, unnecessary measurement steps can be avoided while maintaining confidence in part quality.

Coordinate Measuring Machine (CMM) for Precision Verification

For parts with complex geometry or tight tolerance requirements, coordinate measuring machines (CMM) are used to verify dimensional accuracy and geometric tolerances. CMM inspection allows repeatable and reliable measurement of features such as position, concentricity, flatness, and parallelism.

CMM measurement is typically applied for:

• First article inspection

• Complex or high-precision components

• Verification of critical features before repeat production

This helps ensure consistency between drawings and delivered parts.

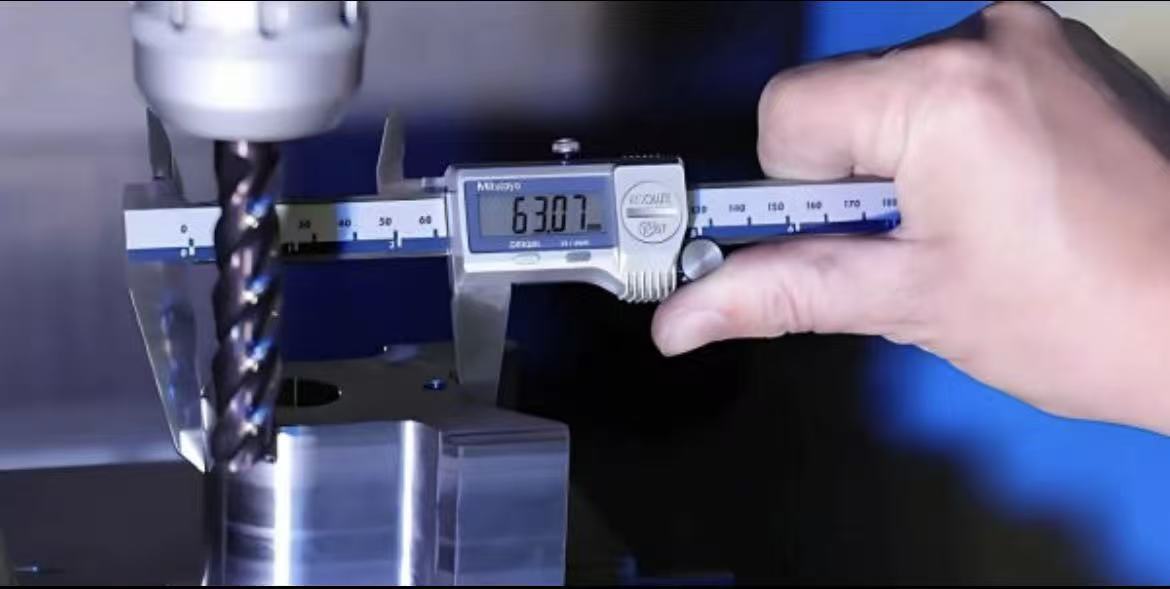

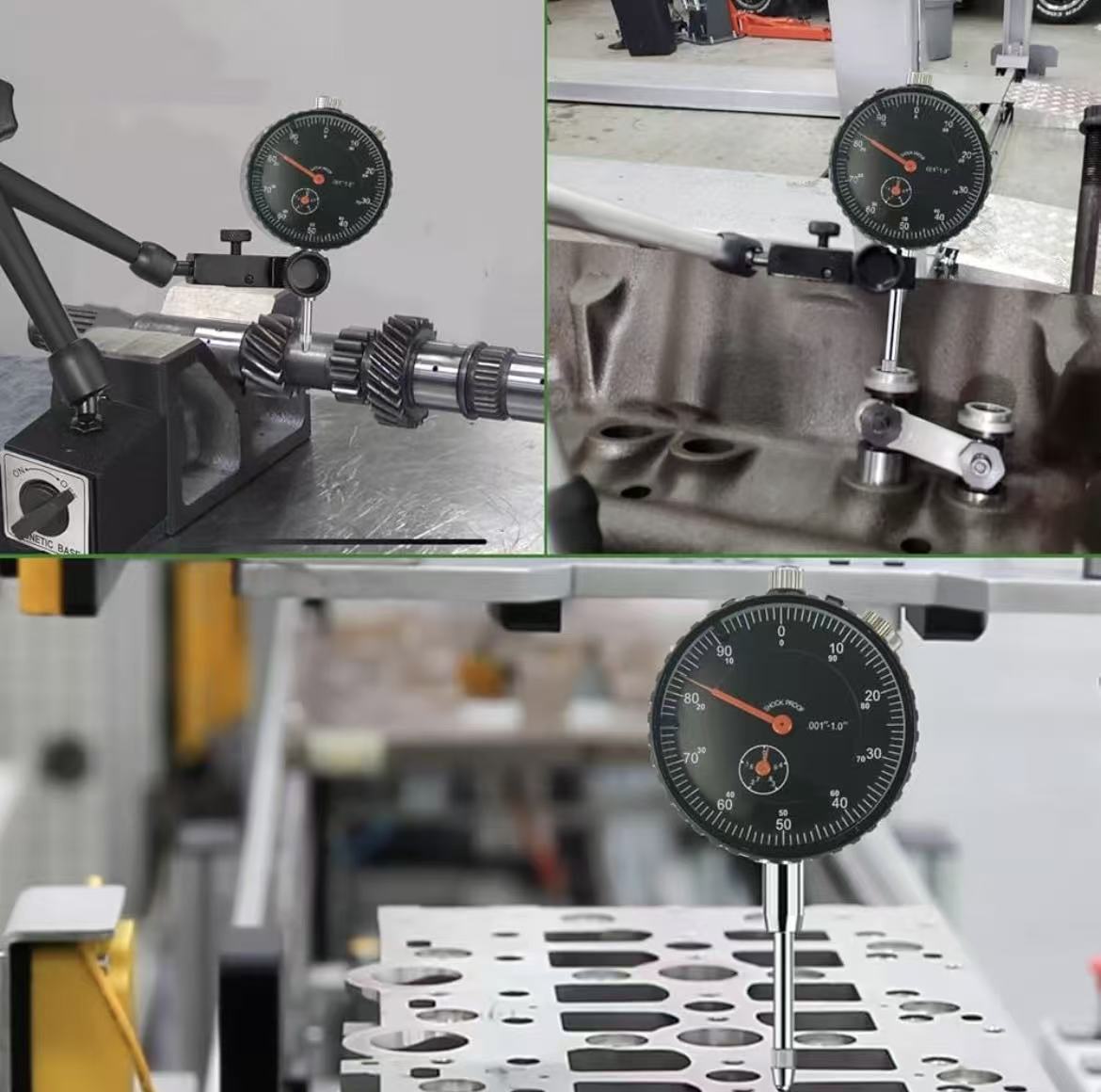

Manual and In-Process Measurement Tools

In addition to CMM inspection, routine dimensional checks are carried out using manual and in-process measurement tools. These tools support efficient control during machining and help detect variation at an early stage.

Commonly used instruments include:

• Digital calipers for general dimensions

• Micrometers for critical thickness and diameter control

• Height gauges for positional and height-related features

• Dial indicators and bore gauges for runout and internal diameter checks

Combining these methods allows inspection to be both practical and effective.

Consistency Across Batches and Repeat Orders

Inspection standards and reference points are kept consistent across production batches. This is especially important for small and medium batch orders where parts must remain interchangeable over time.

By maintaining stable measurement methods and documented inspection practices, dimensional consistency can be achieved even across long-term repeat production.

Supporting Reliable Assembly Through Controlled Measurement

Effective quality inspection is not about achieving the smallest possible tolerance, but about ensuring parts fit and function reliably in real applications. Through appropriate use of CMM measurement and manual inspection tools, parts can be supplied with predictable and verifiable quality.

For customers who require dependable CNC machining services for custom parts, discussions around inspection requirements and tolerance expectations are always welcome.

Contact Us:

Xiamen GSG-Tech Precision Technology Co., Ltd.

Website: www.xmgsgroup.com

Email: info@xmgsgroup.com

WhatsApp: +86 13859969390

Post time: Jan-07-2026