In the evolving world of high-precision engineering, 5-Axis CNC machining has emerged as a cornerstone technology that defines accuracy, flexibility, and performance. At Xiamen Guansheng Precision Machinery Co., Ltd., our investment in state-of-the-art 5-Axis CNC machining centers enables us to produce complex, high-tolerance components for industries that demand nothing less than perfection — from medical devices and automotive parts to industrial automation systems and aerospace components.

What Is 5-Axis CNC Machining?

Unlike traditional 3-Axis machines that move a cutting tool along the X, Y, and Z axes, 5-Axis CNC machines add two rotational axes — A and B — allowing the tool or workpiece to move in five directions simultaneously. This advanced motion control enables the creation of intricate geometries, undercuts, and multi-angled surfaces in a single setup, dramatically improving efficiency and accuracy.

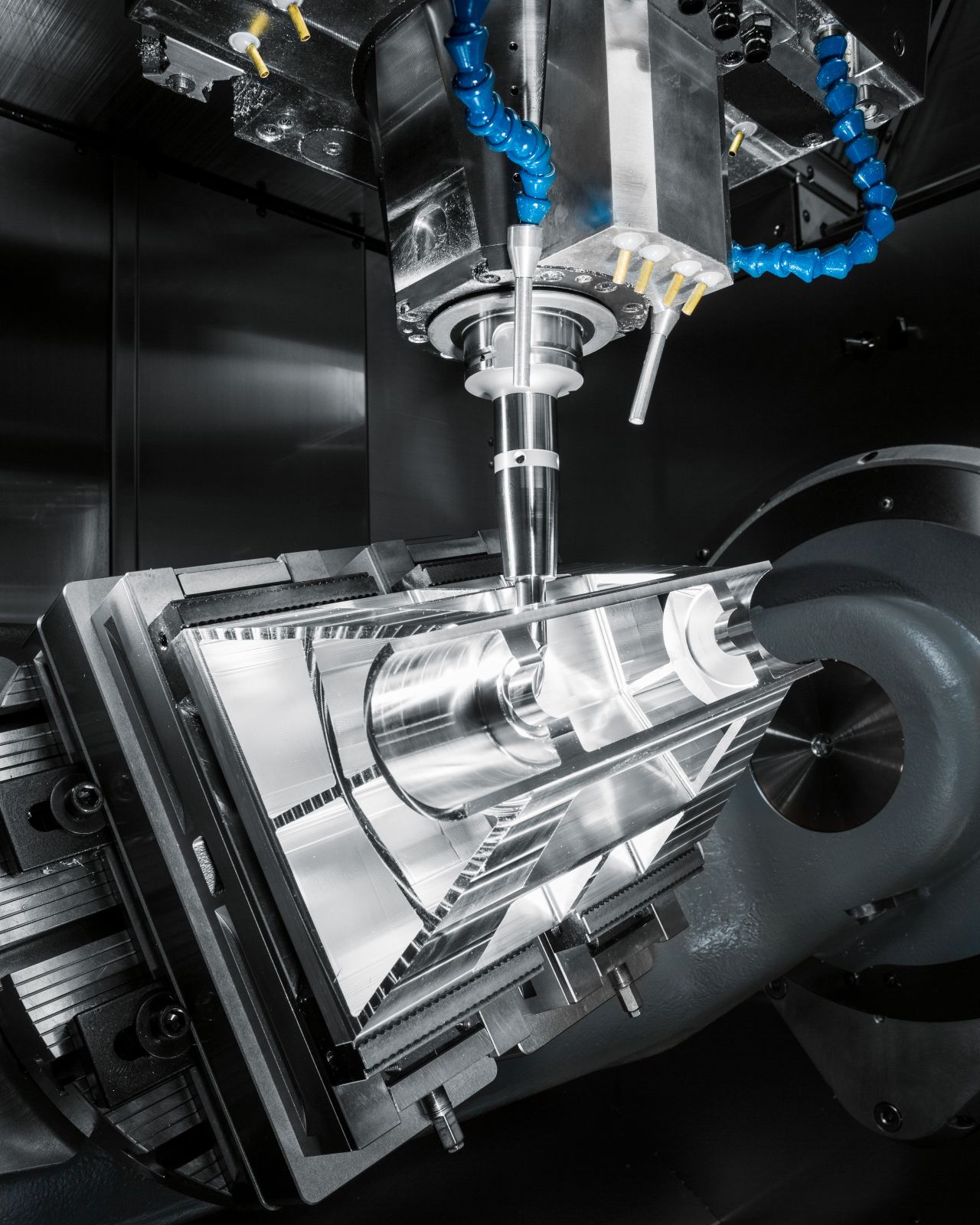

The image above showcases one of Guansheng’s 5-Axis HAAS Machining Centers, a high-precision system equipped with dynamic spindle control, high-speed cutting, and multi-angle clamping technology. These features allow us to machine complex metal components with surface roughness as low as Ra 0.4 μm and dimensional tolerances up to ±0.005 mm — the kind of precision that defines world-class manufacturing.

Precision That Powers Innovation

Whether we’re machining titanium surgical handles, aluminum heat sinks, or aerospace sensor housings, Guansheng’s 5-Axis CNC capabilities ensure that every detail meets the strictest quality standards. This technology reduces the need for multiple setups, lowers the risk of alignment errors, and significantly shortens lead times — all while maintaining exceptional surface finishes and structural integrity.

Our skilled engineers use advanced CAM software and digital simulation to plan tool paths with absolute precision. Combined with real-time inspection and CMM quality verification, we deliver components that meet ISO 9001, ISO 13485, and IATF 16949 certifications.

Applications Across Industries

5-Axis machining is transforming how manufacturers approach complex product design.

At Guansheng, this capability supports:

- Medical Device Manufacturing – producing surgical tool handles, endoscope parts, and orthopedic fixtures.

- Automotive & EV Components – machining lightweight housings, cooling plates, and structural aluminum parts.

- Industrial Automation – precision brackets, gears, and robotic joint parts for smart factory systems.

- Aerospace & Defense – titanium structural components requiring extreme tolerance and reliability.

Guansheng’s Commitment to Excellence

Every component produced at Xiamen Guansheng reflects a commitment to innovation and quality. Our 10,000 ㎡ production facility houses multiple 3-, 4-, and 5-axis machining centers, supported by experienced engineers and a strict quality management system. From prototyping to full-scale production, we help clients achieve faster development cycles, superior product reliability, and competitive costs.

As global industries demand more advanced materials and precision solutions, 5-Axis CNC machining stands at the forefront of modern manufacturing — and Guansheng Precision Machinery is proud to lead the way.

Contact Us

Xiamen Guansheng Precision Machinery Co., Ltd.

Website: www.xmgsgroup.com

Email: info@xmgsgroup.com

WhatsApp: +86 138 5996 9390

Address: Xiamen City, Fujian Province, China

Post time: Nov-14-2025